To anyone who wants to do an ABS delete, here's a short guide.

The master cylinder that is in the top left right of the engine bay with have two outputs on it; a front and a rear. Now with the original ABS, both the front and rear outputs of the master cylinder are routed behind and just to the top of the engine on the bulkhead and go to the ABS module at the rear left of the engine bay. Here the ABS takes the two front and rear inputs and then has 3 outputs; front right, front left, and rear. The front left just goes from the ABS directly to the wheel arch and into the caliper, but the front right and the rear go from the ABS module and again are attached to the bulkhead where the original ABS input lines run. This then makes 4 lines that run behind the engine across of the bulkhead.

Okay, that's how the stock ABS is routed. Now if you want to get rid of the ABS, there are some lines that you will need to run. You may be thinking that there are 4 calipers but only 2 outputs from the master cylinder.

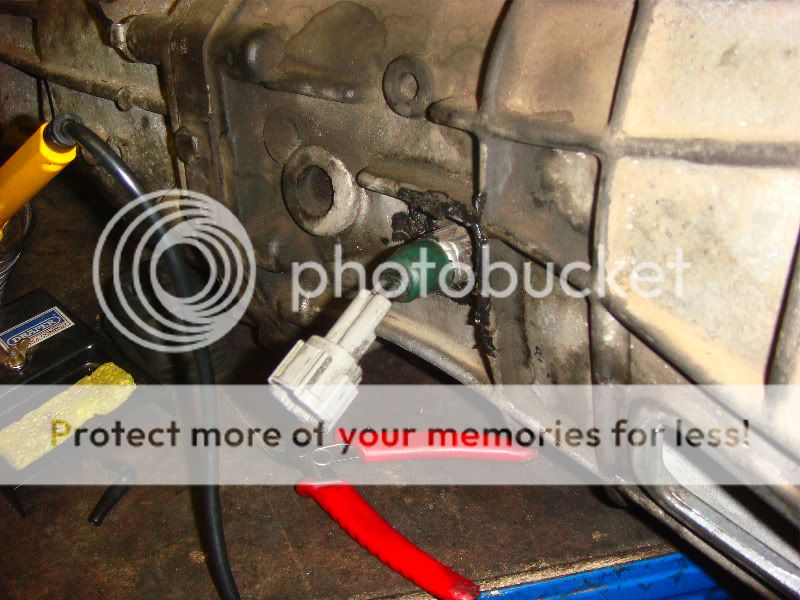

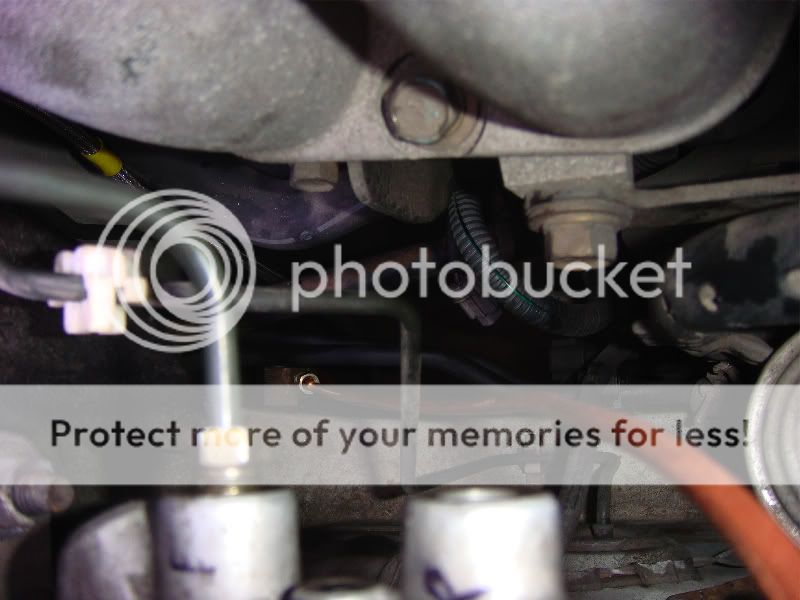

Well lets start on the rears, there is only a single brake line that runs down the car to the rear. At the back of the car there is a T-Piece that splits the rear brake line into 2 to serve the rear calipers. Now at the very start of the transmission tunnel there is a small block that is connected to this line that goes to the rear, you can just about see it in the photo below (where the copper line runs to):

So all you do is connect a line from the master cylinder into this block and that's the rears sorted. Either in that connector or the T-Piece at the rear there is a built in restrictor, so you don't need to worry about brake bias.

Now the next part is the fronts. Since there is only 1 front output from the master cylinder and 2 calipers, you have two choices. You can either get a non-abs brake master cylinder from a skyline or Z32 which will have 3 outputs (front right, front left, rear), or you can just put in a T-Piece and copy the rears.

Check a few posts above for the reasons why I have routed the lines like I have.

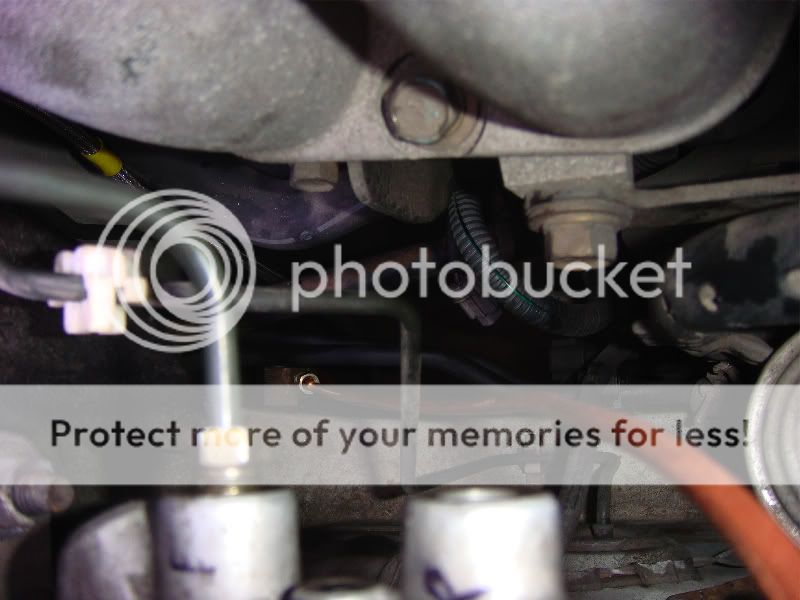

So you're gonna need a T-Piece, I got mine from Vehicle Wiring Products. You will need a one with 10mm x 1 fittings. So you will need to route a line from the BMC to the T-Piece, and then 2 lines from the T-Piece to each of the front calipers. Bare in mind that the T-Piece has concave connectors, so you will need a bubble flare and not a double flare to connect to it. All the other connection in the car like the BMC and the connector near the transmission tunnel will need normal double flares.

Here's a finished photo of the T-Piece showing the connections that go to the front calipers, the black piping goes to the front left and the copper on the opposite side goes back across the bulkhead to the front right caliper. The input at the top is from the BMC.

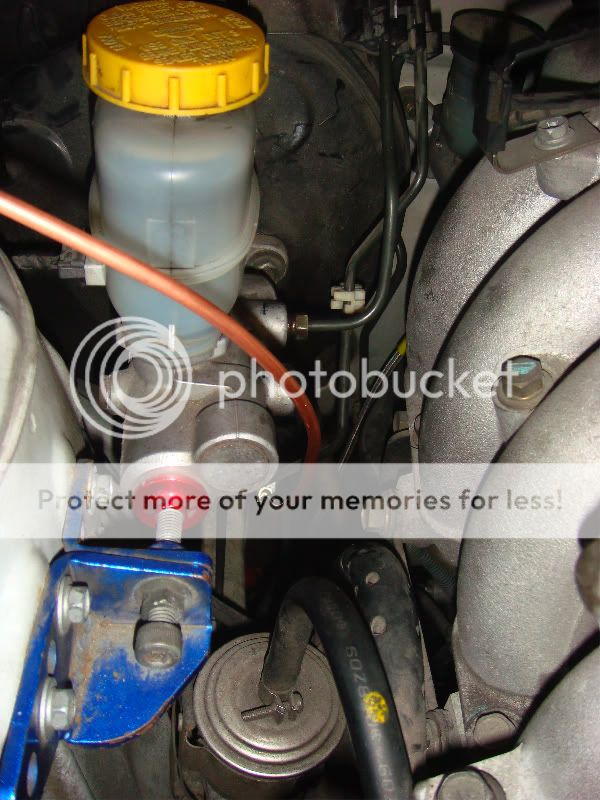

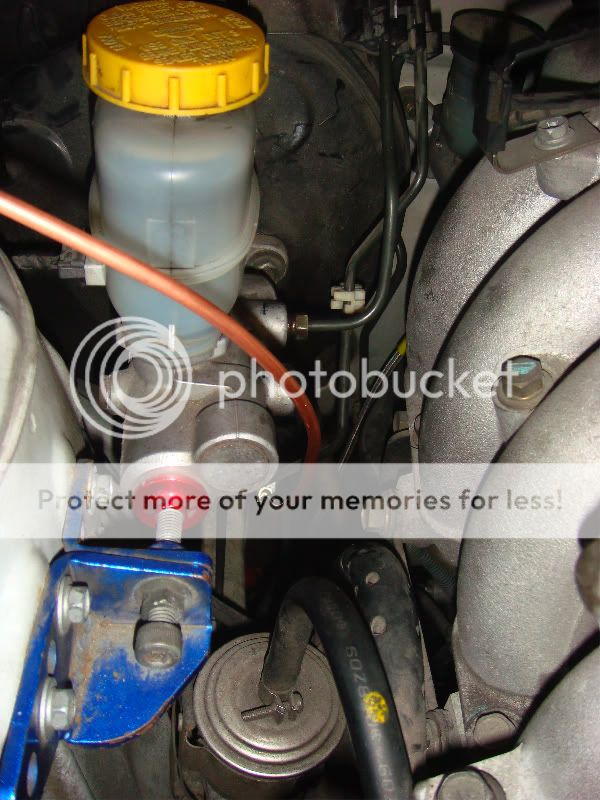

And finally this is how the BMC should look:

I haven't finished it just yet, but you can see that the rear port on the BMC goes has the black pipe that runs across the bulkhead to the T-Piece. You can see the connector for the rears, with a tubing that coming out of it going to the BMC's rear output that I need to finish off and connect.

Edit:

Also when I describe the left or right of the car, it's as if you're sitting in the car and not viewing it from the engine back. So when I say front right caliper, this is the drivers or offside one.

The master cylinder that is in the top left right of the engine bay with have two outputs on it; a front and a rear. Now with the original ABS, both the front and rear outputs of the master cylinder are routed behind and just to the top of the engine on the bulkhead and go to the ABS module at the rear left of the engine bay. Here the ABS takes the two front and rear inputs and then has 3 outputs; front right, front left, and rear. The front left just goes from the ABS directly to the wheel arch and into the caliper, but the front right and the rear go from the ABS module and again are attached to the bulkhead where the original ABS input lines run. This then makes 4 lines that run behind the engine across of the bulkhead.

Okay, that's how the stock ABS is routed. Now if you want to get rid of the ABS, there are some lines that you will need to run. You may be thinking that there are 4 calipers but only 2 outputs from the master cylinder.

Well lets start on the rears, there is only a single brake line that runs down the car to the rear. At the back of the car there is a T-Piece that splits the rear brake line into 2 to serve the rear calipers. Now at the very start of the transmission tunnel there is a small block that is connected to this line that goes to the rear, you can just about see it in the photo below (where the copper line runs to):

So all you do is connect a line from the master cylinder into this block and that's the rears sorted. Either in that connector or the T-Piece at the rear there is a built in restrictor, so you don't need to worry about brake bias.

Now the next part is the fronts. Since there is only 1 front output from the master cylinder and 2 calipers, you have two choices. You can either get a non-abs brake master cylinder from a skyline or Z32 which will have 3 outputs (front right, front left, rear), or you can just put in a T-Piece and copy the rears.

Check a few posts above for the reasons why I have routed the lines like I have.

So you're gonna need a T-Piece, I got mine from Vehicle Wiring Products. You will need a one with 10mm x 1 fittings. So you will need to route a line from the BMC to the T-Piece, and then 2 lines from the T-Piece to each of the front calipers. Bare in mind that the T-Piece has concave connectors, so you will need a bubble flare and not a double flare to connect to it. All the other connection in the car like the BMC and the connector near the transmission tunnel will need normal double flares.

Here's a finished photo of the T-Piece showing the connections that go to the front calipers, the black piping goes to the front left and the copper on the opposite side goes back across the bulkhead to the front right caliper. The input at the top is from the BMC.

And finally this is how the BMC should look:

I haven't finished it just yet, but you can see that the rear port on the BMC goes has the black pipe that runs across the bulkhead to the T-Piece. You can see the connector for the rears, with a tubing that coming out of it going to the BMC's rear output that I need to finish off and connect.

Edit:

Also when I describe the left or right of the car, it's as if you're sitting in the car and not viewing it from the engine back. So when I say front right caliper, this is the drivers or offside one.

Last edited: