Ah 2 weeks and you will be blasting about ! Bit jealous I must admit gonna be awesome man

More pics would be superb

They will come, I promise.

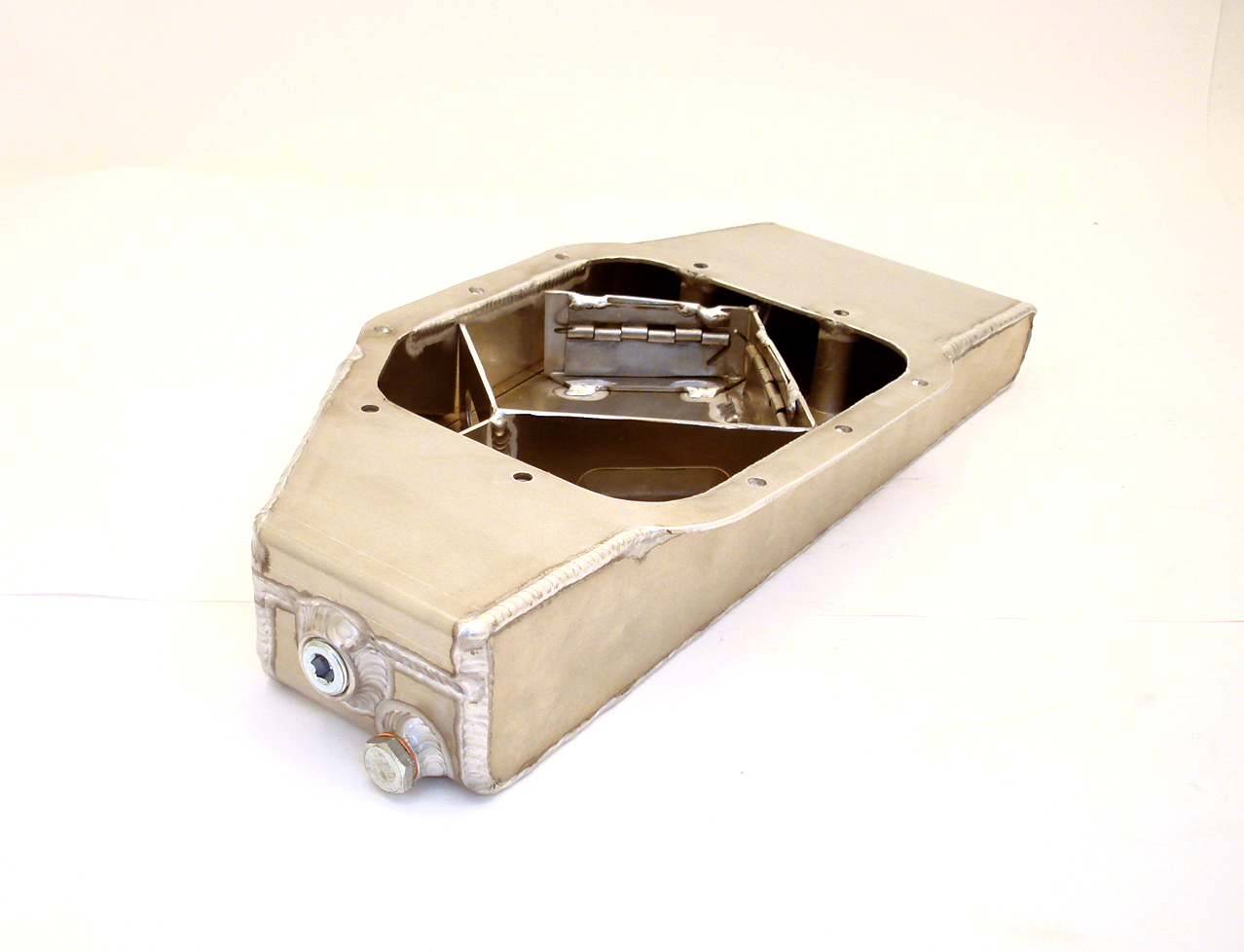

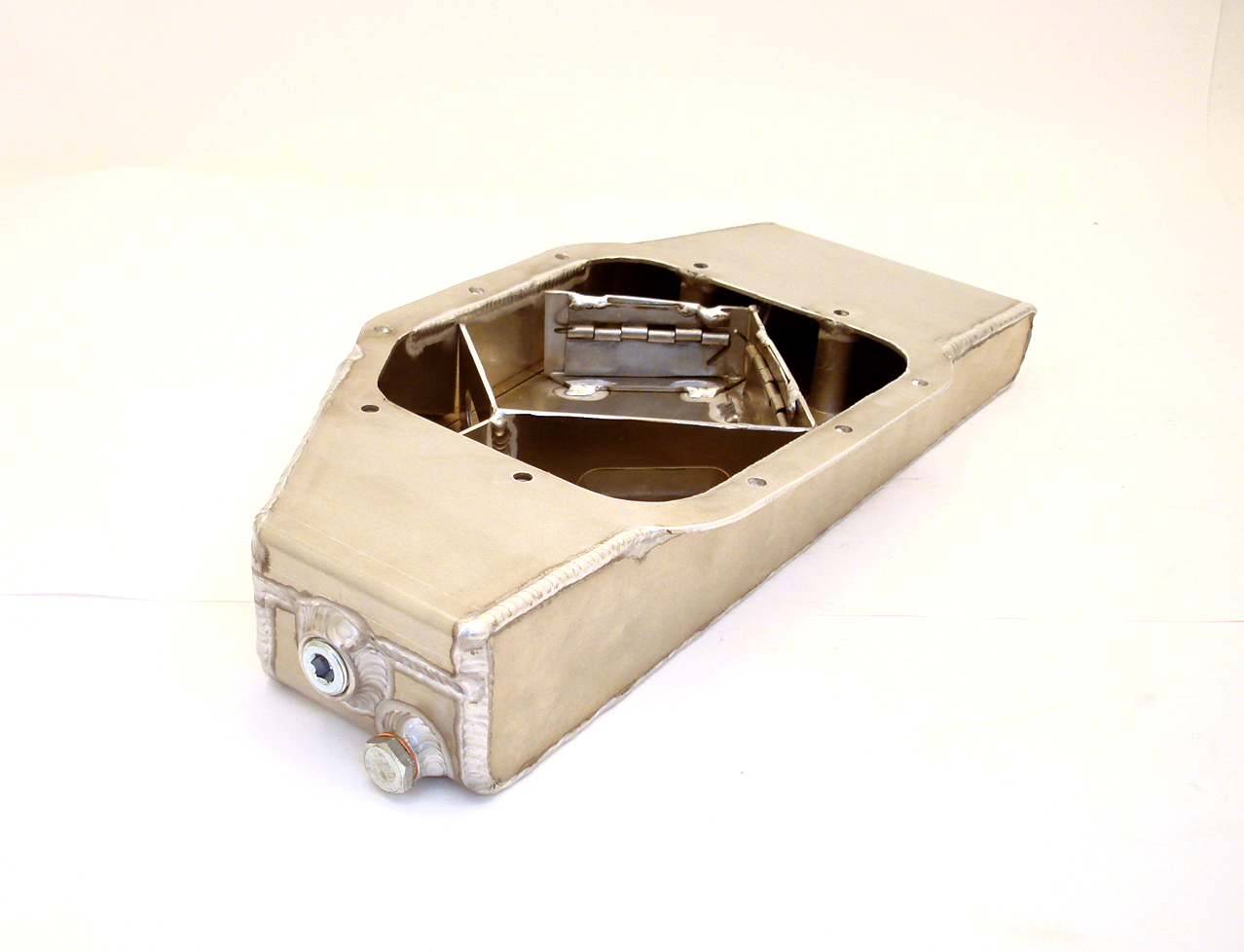

In the mean time, which sump....

Canton £234 delivered + tax

or Tomei £250 delivered (will take longer) + tax

I prefer the look of the welded designs and I think they are a bit tougher than the cast versions, and easier to repair. I have seen one example of a hinge coming off a Tomei one and blocking the oil pickup.

The Canton one is pretty unique, turning forces plus braking and accel all sorted! Welds look very nice too

Opinions?

In the mean time, which sump....

Canton £234 delivered + tax

or Tomei £250 delivered (will take longer) + tax

I prefer the look of the welded designs and I think they are a bit tougher than the cast versions, and easier to repair. I have seen one example of a hinge coming off a Tomei one and blocking the oil pickup.

The Canton one is pretty unique, turning forces plus braking and accel all sorted! Welds look very nice too

Opinions?

well when entering a corner backwards at speed whilst sliding.. you will have a good oil pickup

like so

like so

Last edited:

S15_SAM

NisSam

- Joined

- 21 February 2011

- Messages

- 1,915

- Reaction score

- 0

- Points

- 0

- Location

- Chippenham, wiltshire

- Country

-

One solution would be to come straight out of the intercooler with a short straight silicone pipe and then get a 180 horse shoe hard pipe, connected to a silicone 70-90 ish degree pipe? Sort of creating a loop in the old battery tray area!

the fan will get in the way if you try and connect directly to each other maybe?

Gona be a pain to sort, any other ideas?

the fan will get in the way if you try and connect directly to each other maybe?

Gona be a pain to sort, any other ideas?

Yeh, I had thought that was about the only non-cutting solution. What put me off was the 180deg bend robbing me of a bit of boost as Air really wants to go as straight as possible. :s

The last manifold and TB was going be alot further away, and closer to the fuse box, so giving me a bit more space. At least I don't have to move the fuse box though!!!

As it is this afternoon I have been running about like a blue arsed fly to find an Ali welder who can re-weld my intercooler end tank! Successfully fortunately. I am now waiting for a 76mm 90degree aluminium bend to get chopped up and made into an end tank.

Making a template tonight!

Phew is all I can say. Tuning in 6 days!!

The last manifold and TB was going be alot further away, and closer to the fuse box, so giving me a bit more space. At least I don't have to move the fuse box though!!!

As it is this afternoon I have been running about like a blue arsed fly to find an Ali welder who can re-weld my intercooler end tank! Successfully fortunately. I am now waiting for a 76mm 90degree aluminium bend to get chopped up and made into an end tank.

Making a template tonight!

Phew is all I can say. Tuning in 6 days!!

S15_SAM

NisSam

- Joined

- 21 February 2011

- Messages

- 1,915

- Reaction score

- 0

- Points

- 0

- Location

- Chippenham, wiltshire

- Country

-

Awesome news! Yeah the loop would have been a massive compromise! Have you had it running atall yet?

Plan is still evolving. The bent tube idea still requires a bit more room, so I'm just transforming the end tank into a right angle so point right at the TB.

Shortest Cold pipe EVER

Template taking shape

Maybe not the perfect flow solution but time pressures are forcing my hand a bit!

Shortest Cold pipe EVER

Template taking shape

Maybe not the perfect flow solution but time pressures are forcing my hand a bit!

This is exactly what I was going to suggest! Sure it will be fine mate ! Plenty of time yet

S15_SAM

NisSam

- Joined

- 21 February 2011

- Messages

- 1,915

- Reaction score

- 0

- Points

- 0

- Location

- Chippenham, wiltshire

- Country

-

In your previous pictures it looked like the fan cowling is in the way? Have you tried the template with the cowling?

Got access to a TIG? if so i would cut into the end tank and make a exit pipe angled at your TB, while in there i wold also put a vertical baffle to two too direct air flow so at to not have a pressure build up just as it leaves the intercooler, but how much time do you have im guessing thats a good 6 - 7 hours of work. You might have to just sacrifice that corner off your fan frame, im guessing the fan blade is far enough away.

Or for now just so it can be running, until you have got time to fabricate something like that, a 90' silicone + 45' will get you running with a bit of rubbing or you fan frame

Or for now just so it can be running, until you have got time to fabricate something like that, a 90' silicone + 45' will get you running with a bit of rubbing or you fan frame

Ah yeh, the fan shroud. The fan blades are miles away fortunately, and the amount of air those things shift when they come on I am not worried about losing the corner

I do agree that I could do with a more elegantly welded solution. I'll have the bloke that is welding it chops the right angled corner off and weld in a plate so that it is a bit more of a passageway for the air rather than a box.

Im pretty sure it is all too tight for using any silicone, especially as I have to bump up the diameter of the pipe to 83mm for the throttle body. Fat tubes!

I do agree that I could do with a more elegantly welded solution. I'll have the bloke that is welding it chops the right angled corner off and weld in a plate so that it is a bit more of a passageway for the air rather than a box.

Im pretty sure it is all too tight for using any silicone, especially as I have to bump up the diameter of the pipe to 83mm for the throttle body. Fat tubes!

That is one insanely cool looking bay ! Ha be well worth the hassle then

Looking good :thumbs:

Total Nissan engine porn. I'd marry that car

I dont have the stock fan and shroud setup either (twin electric with shroud), so i had to cut that exact same corner off to accommodate intercooler piping, providing there is a bit of plastic frame that goes around the fan itself it should not lose too much strengthAh yeh, the fan shroud. The fan blades are miles away fortunately, and the amount of air those things shift when they come on I am not worried about losing the corner

I do agree that I could do with a more elegantly welded solution. I'll have the bloke that is welding it chops the right angled corner off and weld in a plate so that it is a bit more of a passageway for the air rather than a box.

Im pretty sure it is all too tight for using any silicone, especially as I have to bump up the diameter of the pipe to 83mm for the throttle body. Fat tubes!

About Us

This owners club has been made in the benefit of owners of the Nissan Silvia chassis, allowing them to socially integrate and share their knowledge and advice.

We also intend to create events and social activities for members to take part in to help members meet and get to know each other.

We also intend to create events and social activities for members to take part in to help members meet and get to know each other.

Online statistics

- Members online

- 0

- Guests online

- 193

- Total visitors

- 193

Totals may include hidden visitors.