BTW, I've merged your 2 threads as they were of the same topic, just in different sections

Thanks for that I was going to ask you if you could do that, the original build thread had been inactive for ages but just got some new posts, cheers

I see, was thinking bout this as some of the paint doesn't match the best from previous work.. It's not bad just noticeable in some lightsIf you get someone to paint the car who has experience with painting pearls, or better still WK0 pearl white, then there won't be any problems. You can't just paint one panel though. If you fit a bodykit you'll have to paint most of the car in order to blend the colour.

Actually if i'm critical of the kit paint I have to agree that in some light/angles you can see a difference in shade but in general it's not noticable. I'm going to have the car detailed specificaly to have the paint corrected with a rotary, this should help with the colour matching between the panels. will let you know how i get on.

G

gr8guy

Guest

Hi ichigo

where did u get the EPR CF Radio Surround from?

where did u get the EPR CF Radio Surround from?

Hi and welcome..

The radio surround came from EPR Racing in the UK

http://www.epracing.co.uk/Carbon-Ac...round-&-Radio-Surround/p-75-122-131-136-1578/

It's very well made with a great finish, but it did need some trimming with a dremmel to make it all fit correctly. Not cheap though..

The radio surround came from EPR Racing in the UK

http://www.epracing.co.uk/Carbon-Ac...round-&-Radio-Surround/p-75-122-131-136-1578/

It's very well made with a great finish, but it did need some trimming with a dremmel to make it all fit correctly. Not cheap though..

G

gr8guy

Guest

thanks ichgo

update

Been a bit quiet recently due to my move to the states, but have had a few things done on the car.

The rear end action since day one was and I can't describe it any other way other than Dangerious!!

Just changing lanes on boost had the car sideways, coming off boost even in a straight line had the read end twitching, so decided to have the subframe bushes and all the rear arm bushes replaced with Energy Suspension items and the Diff bushes replaced with Driftworks solid ones

The difference is incredible, even without adjustable arms sorting the geometry the rear end is now tight as a tight thing, super grip and general amazing difference, if you've not had this done do it....

Actualy the rear Potenza RE050A's probably havn't hurt either.

Been a bit quiet recently due to my move to the states, but have had a few things done on the car.

The rear end action since day one was and I can't describe it any other way other than Dangerious!!

Just changing lanes on boost had the car sideways, coming off boost even in a straight line had the read end twitching, so decided to have the subframe bushes and all the rear arm bushes replaced with Energy Suspension items and the Diff bushes replaced with Driftworks solid ones

The difference is incredible, even without adjustable arms sorting the geometry the rear end is now tight as a tight thing, super grip and general amazing difference, if you've not had this done do it....

Actualy the rear Potenza RE050A's probably havn't hurt either.

Would have loved to have done a Dean and Craig and detailed the rear end but that'll have to wait until I'm back in the UK, also all the rear arms and rear lower control arms plus the front control arms and tie rods/end are being replaced, just the Tein Tensions rods are remaining, more on this later...

The difference this makes is epic. I can pin mine round corners in 2nd and the back end just grips. Bet your looking forward to getting back to the UK for a drive?!

you have no idea

DeanS15

My car is so clean you could eat off it.

Makes a massive difference, well worth doing  I'm finding the handling great butmsometes too sharp where it reacts to crappy uk roads. When you find a nice smooth one it's lovely

I'm finding the handling great butmsometes too sharp where it reacts to crappy uk roads. When you find a nice smooth one it's lovely

Good work dude,hoping to do mine over winter this year fingers crossed!

Cars looking nice though mate

Cars looking nice though mate

Cheers and if you get a chance over the winter it's well worth the hastle, big difference.

If anyones interested here's the Energy Suspension part numbers for the subframe bushes and the rear arm bushes

If anyones interested here's the Energy Suspension part numbers for the subframe bushes and the rear arm bushes

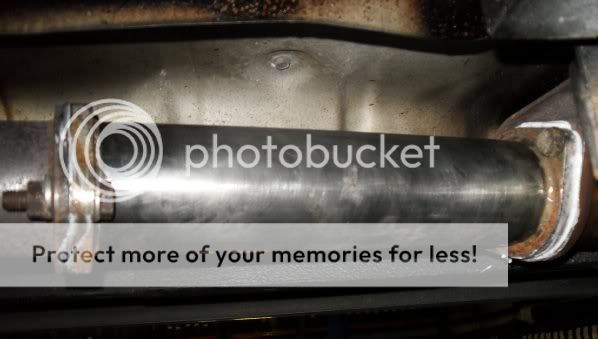

another bit of work that was done recently. The Decat - got a nice Apexi one from Jap Performance Parts.

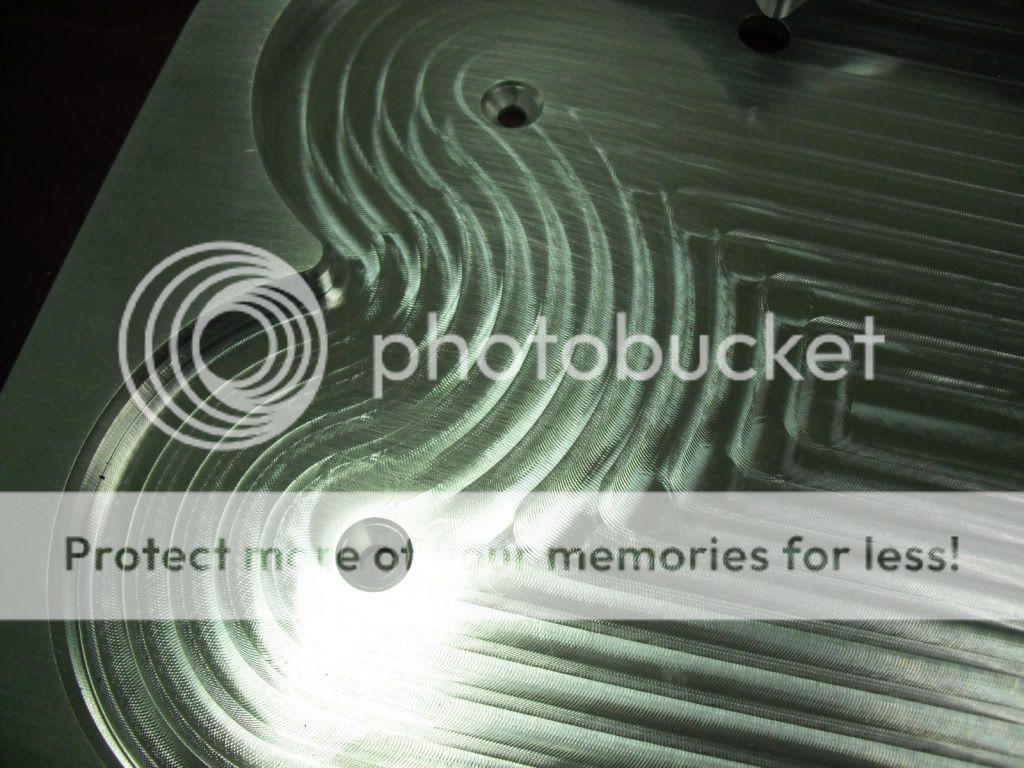

I'm doing a battery relocation to the boot as I want to make some space in the engine bay and have been looking around for a nice bracket to hold the Optima Yellow Top i'm getting, found one here in the states that's compliant with the US NHRA as is uses 3/8" bolts for mounting so should do fine for day to day and track use back home  . CNC machined out of solid billet 6061-T6 Aircraft Grade Aluminium.. Nice. Turned up today.

. CNC machined out of solid billet 6061-T6 Aircraft Grade Aluminium.. Nice. Turned up today.

Will post some pics once it's in and the Optima's wired up. Need to sort my plans for the sounds install first as there will be a far bit of wiring and distribution to sort as part of the battery install but getting there.

Will post some pics once it's in and the Optima's wired up. Need to sort my plans for the sounds install first as there will be a far bit of wiring and distribution to sort as part of the battery install but getting there.

Looks awesome!! Why aren't there things like that over here!!!

I know... and it only cost £50 shipped lol.... Would pay loads for something like this back home......

This was the cheapest of the brackets they sell, they also make custom ones with your own design machined into it...

http://optimatrays.com/

Now thinking about getting two of these so I can run a split charge set up for the hifi install, more on this later.....

This was the cheapest of the brackets they sell, they also make custom ones with your own design machined into it...

http://optimatrays.com/

Now thinking about getting two of these so I can run a split charge set up for the hifi install, more on this later.....

Last edited:

- Joined

- 26 January 2011

- Messages

- 108

- Reaction score

- 0

- Points

- 0

- Location

- Gold Coast, Queensland, Australia

- Country

-

Want to make me one of those trays? Looks sick!

Sr23vet slow build

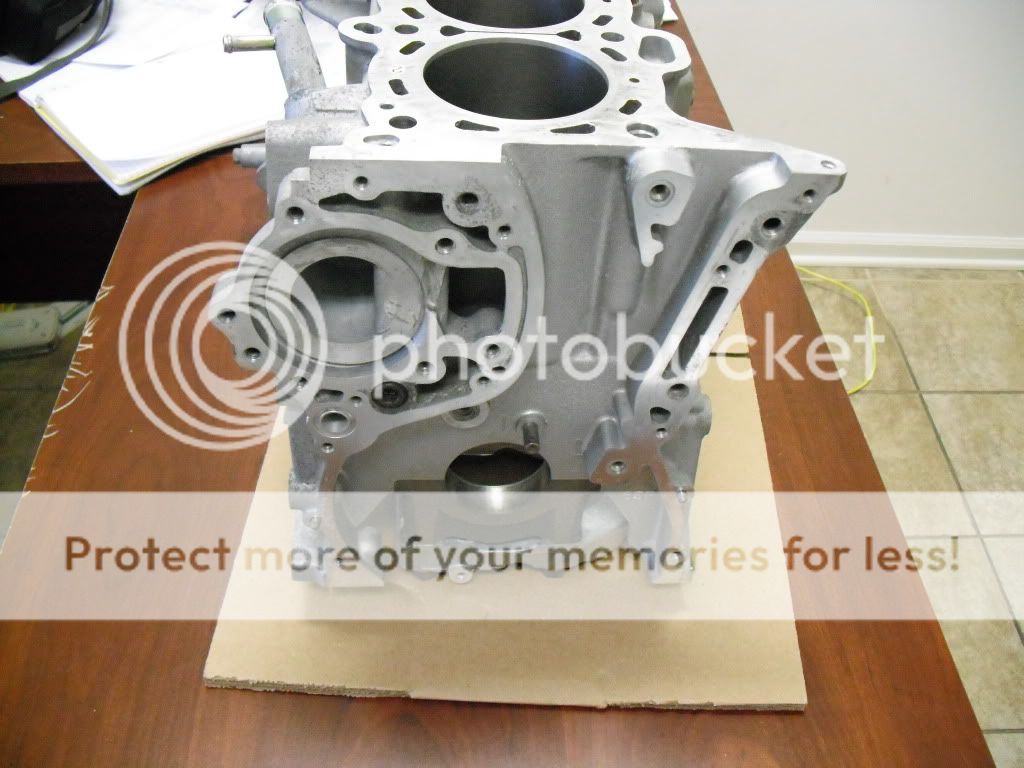

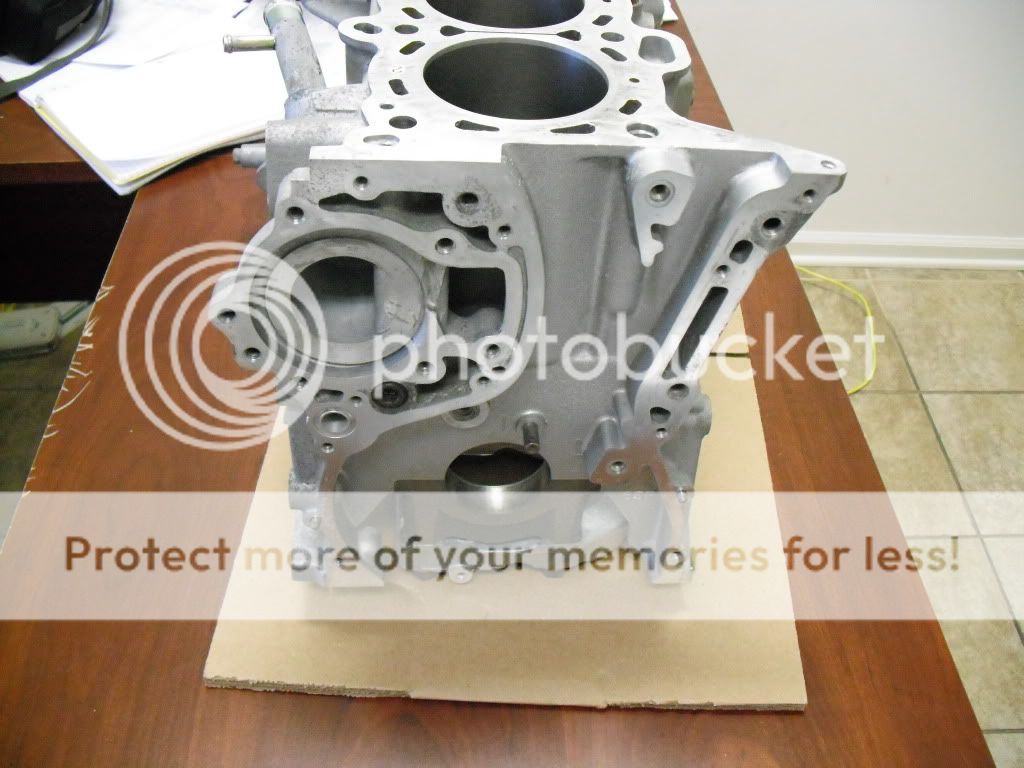

I'd originaly intended to build a solid 400bhp motor, with forged internals and solid lifters for high rpm use, so I bought most of what I needed including bored and honed block (86.5mm), micropolished crank, water pump, oil pump/front cover, 740cc Nismo injectors, Tomei FPR, Garrett GT2871r, HKS Fcon V Pro 3.3 etc etc. But not the rods and pistons, head parts got were BC springs and Titanium retainers, super tech valve stem seals and Tomei RAS.

Since then (late last year) i've moved to the US and my plans have changed (coming back to the UK in 2013 sometime)

I'm now going to build a SR23VET, P11 head and the full works for both (all machining and assembly by Mazworx), it's going to be a slow build mainly due to funds but also because I want to ship various parts of the build to WPC Treatments (http://www.wpctreatment.com/) in California for their metal treatment including the block (after the Darton sleeve install, bore and hone), crank, rods, bearings and head parts, plus 'Swain Tech ceramic coatings - Similar to Zircotech' and 'Callico DLC on the wrist pins'. So logistics wise it's gonna take some doing.

This is the plan: -

Mazworx intake manifold/fuel rail

90mm Plazmaman throttle body

Injector Dynamics 2000 injectors

Mazworx Top Mount Exhaust Manifold – V Band (Swain Tech Coated)

Garrett GTX3071r with Tial Exhaust housing (0.64a/r) (V Band)

Tial MR-V 44mm Wastegate

90mmx91mm Engine

Cylinder Head

Core SR20VE Cylinder Head (P11)

Supertech Dual Valve Spring, SR20VE, 123lbs on the seat, for turbo

Supertech Titanium Retainers, SR20

Supertech Nissan 6mm Exh Guide, DE/VE

Supertech Valve Guide Intake Nissan SR20DET/RB26 6 mm stem Manganese Bronze

Supertech Intake Valve Stem Seal, SR20

Supertech Exhaust Valve Stem Seal, SR20DE

Supertech Intake Valve, +1mm, SR20VE

Supertech Iconel Exhaust Valve, +2mm,SR20VE

Supertech Inner Spring Locator, 6mm Valve,SR20

Kelford Racing Cams, SR20VE, High RPM Turbo duration (WPC Treated)

Tomei Adjustable Cam Gears

Mazworx 1/2" Head Stud Kit w/ Dowels

Mazworx SR20DET Headgasket, 90mm Bore

Clean and R/R Oil Ports

CNC Combustion Chamber, 90mm Bore

Stage 2 Port and Polish Gasket Match, Bowl Work, Blend and Polish

Competition Valve Job, VE

Resurface Head

R/R Valve Guides

SR 1/2" Stud Machining, Head

Machine Headgasket for 1/2" Head Studs

Assemble/Shim (Solid Pivots)

Block

S15 Core Block

Darton Nissan SR20 Dry Sleeve, Double Flat

Darton Nissan SR20 Dry Sleeve, Single Flat

Oil Pump, SR20VE (Blueprinted and WPC treated)

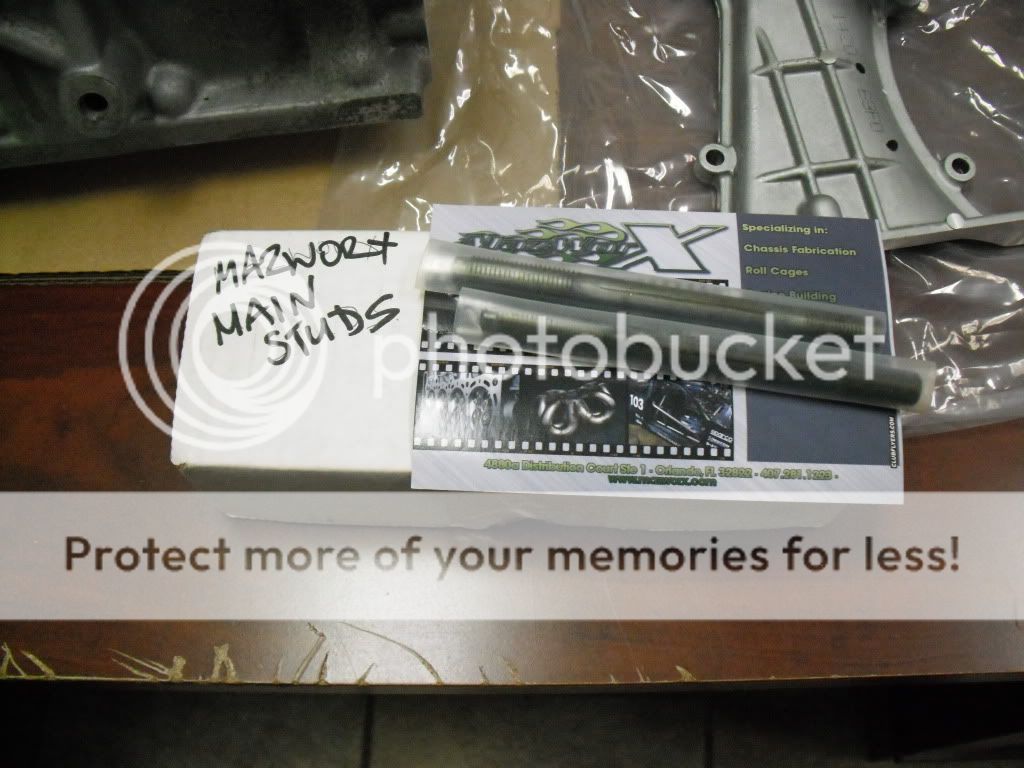

Mazworx SR20 Main Stud Kit

4 Custom CP Pistons (set of 4) -- 90mm 9.0:1 VE Head (special profile for CNC Combustion Chamber machining) (Swain Tech Coating – Gold Coat piston top and PC-9 Skirt Coating) (Calico DLC coated ‘wrist pins’)

Carrillo H Beam Connecting Rods, SR20, CARR Bolts

Mazworx SR20 91mm Billet Crankshaft

Callico coated ACL Race Thrust Bearing, Nissan SR20

Callico coated ACL Race Rod Bearing 19mm Wide SR20DET

Callico coated ACL Race Main Bearing Set, NissanSR20DET, w/ 5 Oiling Holes

Nismo Pilot Roller Bearing

ATI Super Damper, SR20 RWD

Oil Pickup, SR20

SR20VE Oil Pickup Assy

Water Pump, S15, SR20

Greddy High Capacity Oil Pan, SR20 RWD

Clean and R/R Oil Ports

Sleeve Install

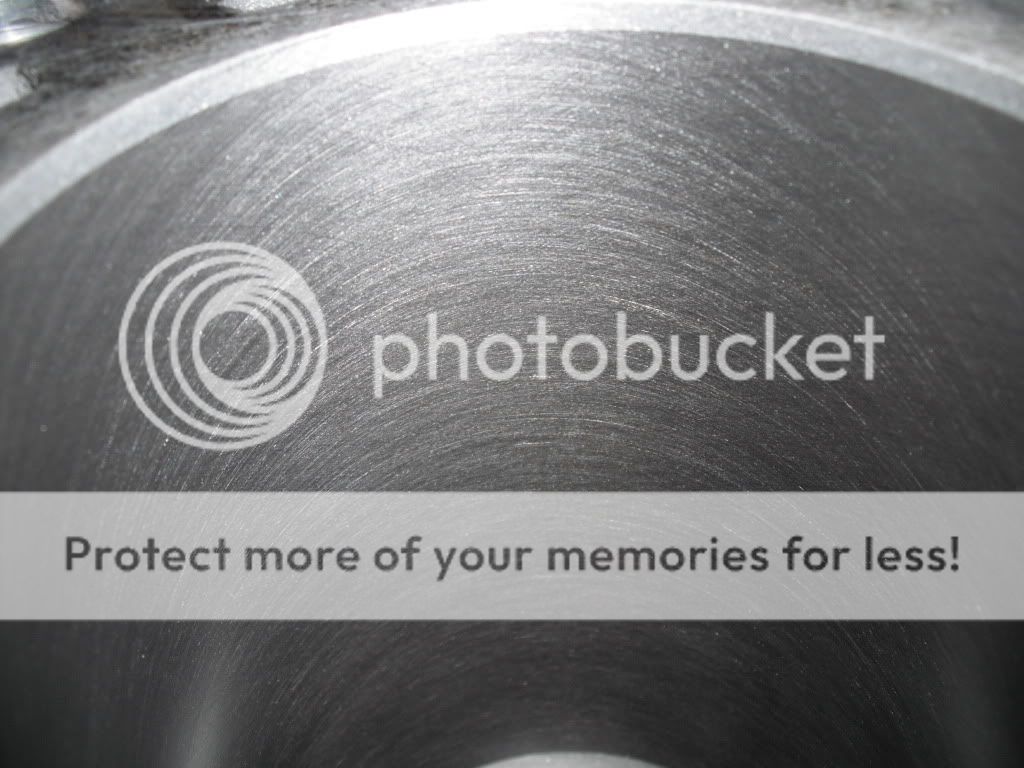

Bore & Hone w/ Torque Plate -- 90MM

Resize Line Bore

Resurface Block & Oil Pump

Oil Groove Machining, SR20

SR 1/2" Stud Machining, Block

19mm Rod Bearing Machining

Weld Oil Pickup

Assemble Short Block

Timing Chain, SR20

Crank Key

Sprocket, Crank, SR20

Timing Chain Tensioner, SR20

Tensioner Gasket

Timing Chain Guide, Fixed, SR20

Timing Chain Guide, Adjustable, SR20

Bolt, Adjustable Chain Guide

Mazworx SR20 Bolt Kit, Fixed Timing Chain

Guide

Labor Assemble Short Block/Degree Cams

Should be good for 550bhp with this turbo, it's intensionaly a small turbo as I want max response rather than chasing hp figures.

This is what i've got so far: -

Cleaned, bored and honed to 86.5mm (shame it's being machined out)

New Water Pump

New front cover/oil pump (can't use this now need a VE version to clear the head)

New oil filter relocation adaptor

Prepped DET head with new springs and titanium retainers (no good to me now so will be selling)

Main studs

I'll be posting up progress on the build fairly regularly, next on the list to buy: -

Greddy Oil Pan

ATI Pulley

Next to do: -

Refurb my spare S15 alternator and have casing powder coated

Send starter motor (spare) out for polishing

Plus I have a load of brand new in box parts for the old build that i'll be selling.

I'd originaly intended to build a solid 400bhp motor, with forged internals and solid lifters for high rpm use, so I bought most of what I needed including bored and honed block (86.5mm), micropolished crank, water pump, oil pump/front cover, 740cc Nismo injectors, Tomei FPR, Garrett GT2871r, HKS Fcon V Pro 3.3 etc etc. But not the rods and pistons, head parts got were BC springs and Titanium retainers, super tech valve stem seals and Tomei RAS.

Since then (late last year) i've moved to the US and my plans have changed (coming back to the UK in 2013 sometime)

I'm now going to build a SR23VET, P11 head and the full works for both (all machining and assembly by Mazworx), it's going to be a slow build mainly due to funds but also because I want to ship various parts of the build to WPC Treatments (http://www.wpctreatment.com/) in California for their metal treatment including the block (after the Darton sleeve install, bore and hone), crank, rods, bearings and head parts, plus 'Swain Tech ceramic coatings - Similar to Zircotech' and 'Callico DLC on the wrist pins'. So logistics wise it's gonna take some doing.

This is the plan: -

Mazworx intake manifold/fuel rail

90mm Plazmaman throttle body

Injector Dynamics 2000 injectors

Mazworx Top Mount Exhaust Manifold – V Band (Swain Tech Coated)

Garrett GTX3071r with Tial Exhaust housing (0.64a/r) (V Band)

Tial MR-V 44mm Wastegate

90mmx91mm Engine

Cylinder Head

Core SR20VE Cylinder Head (P11)

Supertech Dual Valve Spring, SR20VE, 123lbs on the seat, for turbo

Supertech Titanium Retainers, SR20

Supertech Nissan 6mm Exh Guide, DE/VE

Supertech Valve Guide Intake Nissan SR20DET/RB26 6 mm stem Manganese Bronze

Supertech Intake Valve Stem Seal, SR20

Supertech Exhaust Valve Stem Seal, SR20DE

Supertech Intake Valve, +1mm, SR20VE

Supertech Iconel Exhaust Valve, +2mm,SR20VE

Supertech Inner Spring Locator, 6mm Valve,SR20

Kelford Racing Cams, SR20VE, High RPM Turbo duration (WPC Treated)

Tomei Adjustable Cam Gears

Mazworx 1/2" Head Stud Kit w/ Dowels

Mazworx SR20DET Headgasket, 90mm Bore

Clean and R/R Oil Ports

CNC Combustion Chamber, 90mm Bore

Stage 2 Port and Polish Gasket Match, Bowl Work, Blend and Polish

Competition Valve Job, VE

Resurface Head

R/R Valve Guides

SR 1/2" Stud Machining, Head

Machine Headgasket for 1/2" Head Studs

Assemble/Shim (Solid Pivots)

Block

S15 Core Block

Darton Nissan SR20 Dry Sleeve, Double Flat

Darton Nissan SR20 Dry Sleeve, Single Flat

Oil Pump, SR20VE (Blueprinted and WPC treated)

Mazworx SR20 Main Stud Kit

4 Custom CP Pistons (set of 4) -- 90mm 9.0:1 VE Head (special profile for CNC Combustion Chamber machining) (Swain Tech Coating – Gold Coat piston top and PC-9 Skirt Coating) (Calico DLC coated ‘wrist pins’)

Carrillo H Beam Connecting Rods, SR20, CARR Bolts

Mazworx SR20 91mm Billet Crankshaft

Callico coated ACL Race Thrust Bearing, Nissan SR20

Callico coated ACL Race Rod Bearing 19mm Wide SR20DET

Callico coated ACL Race Main Bearing Set, NissanSR20DET, w/ 5 Oiling Holes

Nismo Pilot Roller Bearing

ATI Super Damper, SR20 RWD

Oil Pickup, SR20

SR20VE Oil Pickup Assy

Water Pump, S15, SR20

Greddy High Capacity Oil Pan, SR20 RWD

Clean and R/R Oil Ports

Sleeve Install

Bore & Hone w/ Torque Plate -- 90MM

Resize Line Bore

Resurface Block & Oil Pump

Oil Groove Machining, SR20

SR 1/2" Stud Machining, Block

19mm Rod Bearing Machining

Weld Oil Pickup

Assemble Short Block

Timing Chain, SR20

Crank Key

Sprocket, Crank, SR20

Timing Chain Tensioner, SR20

Tensioner Gasket

Timing Chain Guide, Fixed, SR20

Timing Chain Guide, Adjustable, SR20

Bolt, Adjustable Chain Guide

Mazworx SR20 Bolt Kit, Fixed Timing Chain

Guide

Labor Assemble Short Block/Degree Cams

Should be good for 550bhp with this turbo, it's intensionaly a small turbo as I want max response rather than chasing hp figures.

This is what i've got so far: -

Cleaned, bored and honed to 86.5mm (shame it's being machined out)

New Water Pump

New front cover/oil pump (can't use this now need a VE version to clear the head)

New oil filter relocation adaptor

Prepped DET head with new springs and titanium retainers (no good to me now so will be selling)

Main studs

I'll be posting up progress on the build fairly regularly, next on the list to buy: -

Greddy Oil Pan

ATI Pulley

Next to do: -

Refurb my spare S15 alternator and have casing powder coated

Send starter motor (spare) out for polishing

Plus I have a load of brand new in box parts for the old build that i'll be selling.

Last edited:

About Us

This owners club has been made in the benefit of owners of the Nissan Silvia chassis, allowing them to socially integrate and share their knowledge and advice.

We also intend to create events and social activities for members to take part in to help members meet and get to know each other.

We also intend to create events and social activities for members to take part in to help members meet and get to know each other.

Online statistics

- Members online

- 0

- Guests online

- 412

- Total visitors

- 412

Totals may include hidden visitors.